Originally to be held at the GSA’s Forres campus but postponed due to global pandemic

March 2020

With Christine Farion’s course on interaction design

Digital Naturalism Laboratories

Institute for Interactive Jungle Crafts

Originally to be held at the GSA’s Forres campus but postponed due to global pandemic

March 2020

With Christine Farion’s course on interaction design

In March 2020, we taught a version of the Copenhagen Institute of Interaction Design’s “Materials of Electronics Course” modified to take place at a field station in Costa Rica with Co-Instructor Paula Te.

Dates: March 9-13, 2020

Location: Las Cruces Research Station, Costa Rica

Photos

https://photos.app.goo.gl/11uvxh1bRgbVkA9d7

(From paula’s documentation)

Course Schedule

https://www.notion.so/Materials-of-Electronics-in-Nature-2020-49e63451ab814496aefb483e49bab6e2

Day 0: Workshop setup (soldering stations, material stations, learning areas, signage, Andy’s in the wild toolkit)

Day 1:

Intro (outside under a bamboo grove). Soldering a drawdio kit. Learning about each of the components, following a trace on a PCB, drawing circuit diagram.

Students make sounds with nature. Record a clip of themselves and share out.

Simplest circuit. Coin cell + LED. Build a coin cell holder. Challenge: Firefly attraction! Create a switch for the LED.

Night hike: use our new LED + switches to mimic firefly blinking patterns. Explore nature at night!

Concepts: traces, conductivity, resistivity, sound & oscillations, energy storage, water + conductivity, timer circuits

Tools: solder, multimeter, wire strippers

Materials: nature, pcbs, drawdio kit, copper tape, coin cell battery, binder clip, LEDs, wire

Day 2:

Simple switch shareout. Circuit review. What if we wanted to power LED with 9V battery? Adding resistor into the circuit, with V=IR.

Build simple circuit with resistor in breadboard.

Solar panels, introduction. Explore range with multimeter and panel. Combine energy with actuation: LEDs, motors, etc. Create charge circuit.

Concepts: energy generation, energy storage, Ohm’s law, overcurrent in LEDs, breadboards

Tools: breadboards, wire strippers, jumper cables

Materials: resistors, solar panels, motors, charge circuit, diodes

Day 3:

Exploring more sensors and actuators. Resistive carbon paint. Photo resistive sensors. Magnetic reed switches, IR sensors. DIY potentiometers

Life sketch with electronics. Mimic something in the environment in electronics. Presenting sketches in the afternoon.

Concepts: sensors and actuators, inputs and outputs,

Tools: hacking in the wild preparedness tools (see Wearable DiNa Studio by Hannah & Andy)

Materials: carbon paint, photo resistive cells, reed switches, IR sensors, potentiometers

Day 4:

Ultimate design exploration: Go out on a hike, ask a question about nature, use the tools you have to answer those questions or learn something about it.

Day 5:

Presentations of explorations and learnings, debrief, and play.

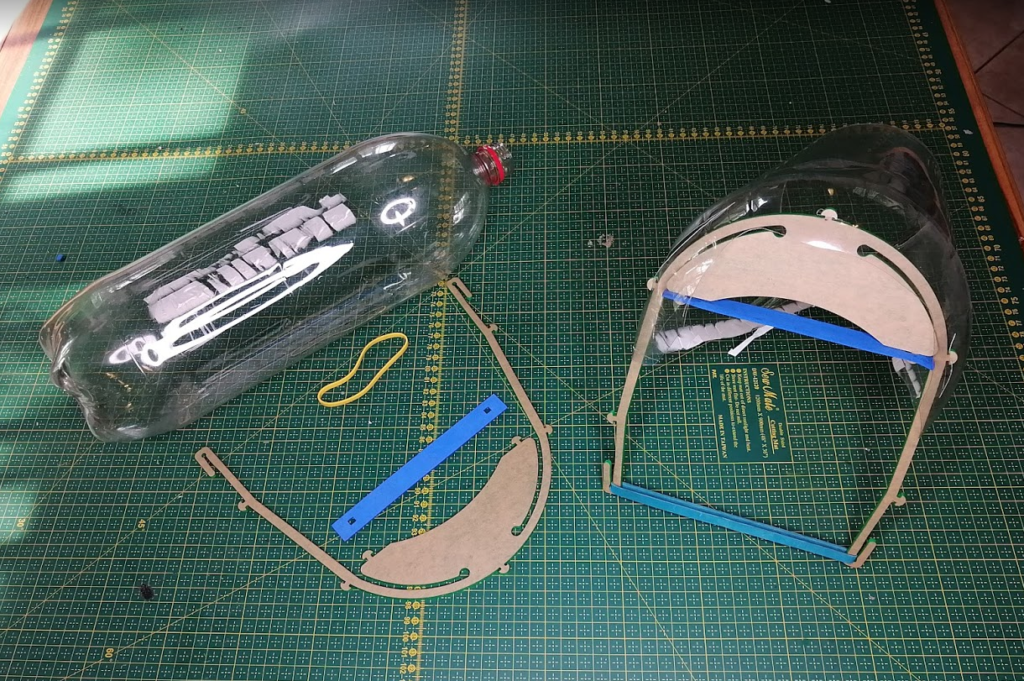

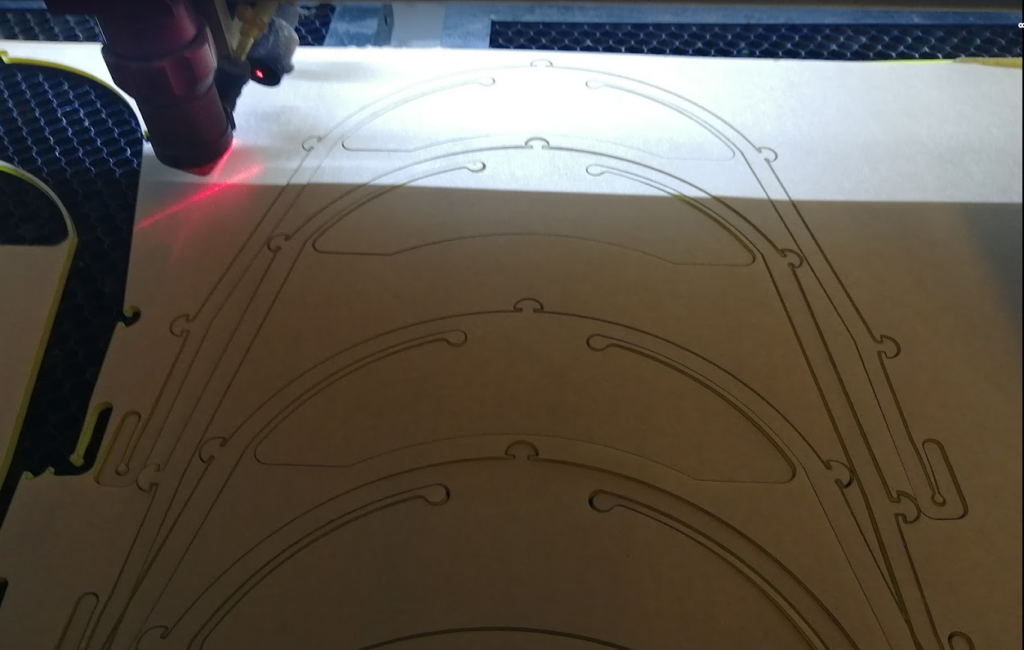

Our little jungle lab is trying to help manufacture face shields for medical workers, and we tested many designs out on the internet. The fastest design we have used so far is our own modification

DOWNLOAD ALL FILES HERE, NO REGISTRATION

https://drive.google.com/open?id=1R7S2vxSGS3DLOInkfokaIpI04cGfVeJM

based off the Georgia Tech Medical Innovation design

https://gcmiatl.com/COVID-19-personal-protective-equipment

The headband just needs

-acrylic-laser cutter

-Rubber band

-(optional) Eva Foam or Self-Adhesive weather stripping (for forehead comfort)

For the face shield, ideally you have thin sheets of PET that you can laser cut as well, but if you don’t you can use A4 transparency sheets (like we will be) or a sliced up 3 Liter soda bottle (like we also use).

The key advantages of this design are

SPEED- Each takes only about 5 minutes to cut, and maybe 8 minutes total to make (compared to 1.5 hours for a 3D print), plus you can nest them to use less material!

and the

USE of LIMITED MATERIALS

-The headbands can be cut out of Acrylic, PET, or most other plastic sheets you might have (could possibly use wood and MDF, but might be harder to sanitize)

-Can attach different types of simple or disposable face shields like A4 transparency sheets or 3 Liter soda bottles

There are plenty of other designs out there that may be nicer or fancier or might make sense if you have a fleet of 3D printers instead of a laser cutter. Figure out what works best with the materials you have. Here in Panama most of the stores except grocery stores are shut down, so most of these materials you can find at the Super 99 grocery store (e.g. EVA foam and Plastic sheets or soda bottles)

For the face shield, ideally you have thin sheets of PET that you can laser cut as well, but if you don’t you can use A4 transparency sheets (like we will be) or a sliced up 3Liter soda bottle (like we also use)

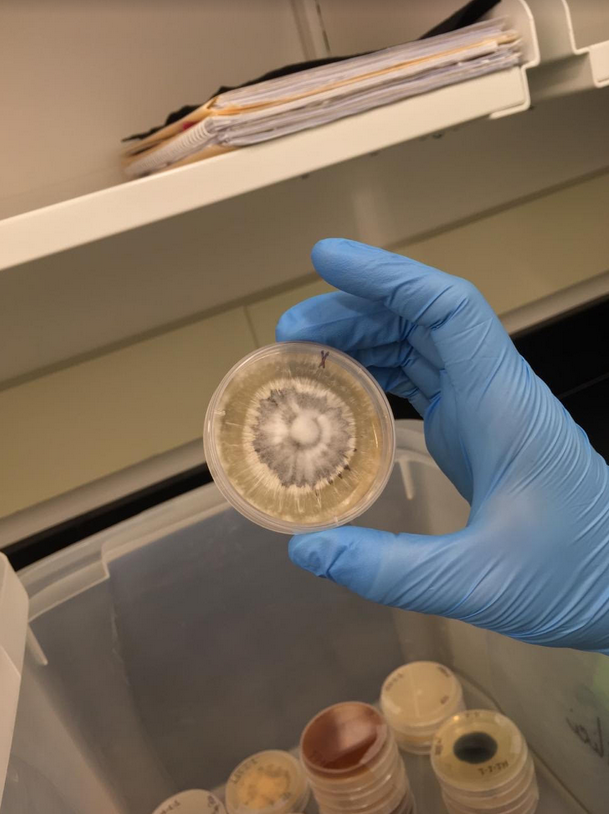

Valerie Milici is a PhD student at UCONN researching the interactions between fungus and roots in tropical saplings.

“I’m Valerie Milici, and I study how fungal diseases that attack baby trees are super important to diversity in the tropical forest. My work takes me from the forest where I make observations and collect field samples, to the greenhouse where I perform experiments, to the lab where I grow up fungal cultures and test to see if they are the diseases attacking seedlings. I love the variation in what I do and how I need to use field skills and lab skills to answer my questions. ”

https://www.instagram.com/ecologically_yours/

Dr. Eran Amichai joined us at Dinalab this January-February. His research is about the sensory role of whiskers in nectivorous bats’ hovering flight. Neotropical nectar-eating bats hover in front of flowers similar to hummingbirds, to feed on the nectar inside while providing pollinating services to the plant. In this project, I investigate the role of the unique arrangement of whiskers these species have, which I hypothesize provide tactile information to the bat about its exact positioning within the flower.

Check out a video of his work!

Dr. Eran AmichaiEcology, Evolution, Environment, and Society (EEES) Graduate ProgramDartmouth Collegehttps://www.researchgate.net/profile/Eran_Amichai Twitter: @EAmichai

Send a message of love via our leafcutter friends! From now until Feb 7, you can place an order with us for $14 per word. We will send you a collection of videos of the ants carrying your words that you can give to whomever you want!

Proceeds help subsidize our scholarships for our local art+science residency program!

Pay via the following options and send an email to andrew.quitmeyer@gmail.com , and we will start filming yours!

if the ants are uncooperative, or we don’t have time to get to yours we will send you a refund!

Square Cash– use a debit or credit card (USA) – https://cash.me/$AndrewQuitmeyer

Paypal – Paypal account or debit cards (international) paypal.me/hikinghack

Venmo – https://venmo.com/hikinghack

(for venmo don’t write that it is for like “conference fees,” just

write like “splitting cost of housing in Panama” which is what you are

doing)

Credit or Debit Cards– (Only use this button below if this is your only option, and you need to add a 5% processing fee that Paypal charges)

Sound on!!

A while ago, I crocheted a túngara, a frog I hear a lot during the wet season in Panamá. I wanted to have my model make the distinctive túngara call, which sounds like a video game sound effect, but I didn’t know how. For Christmas, Andrew gave me a bunch of cool electronics that I can record on and embed in soft toys. He even loaded one with a recording of a túngara for me!

We opened the frog up and inserted the device.

Here’s a picture of a real túngara with its characteristic inflated dewlap.

I’m looking forward to making more noisy toys like this! Someone suggested a toucan, which should be fun.

Note: This post is by Kitty and is cross-posted over all my personal blog, wellreadpanda.com 🙂

Gamboa, Panama – Various Months in 2020

We are happy to announce that applications are open for our new Art/Science/Tech residency program for 2020! Come be a Junglepunk!

The goal of Digital Naturalism Laboratories (DINALAB) is to provide a space with access to incredible natural ecosystems, digital tools, and prototyping equipment to explore new ways of interacting with other creatures. Our new residency program shares the opportunity to explore art, science, technology, and design for an extended period of time in the rainforest. Our lab is situated walking distance from the Panama Canal, the Soberanía Rainforest in Panamá, and the Smithsonian Tropical Research Institute.

What we provide:

Your Responsibilities and Costs:

Unfortunately, we are a new, independent, unfunded lab, and cannot offer a stipend or travel support. We do, however, work hard everyday here at freelance jobs to subsidize your housing costs ourselves, and we even offer a couple scholarships. The basic residency’s costs and responsibilities are:

Scholarships

In 2020, we are happy to announce that we can offer :

Application:

Applications have a priority deadline of January 10, and positions are filled on a rolling basis throughout 2020. Fill out our short form indicating your intentions for the residency and availability, and we will get back to you if you are selected to solidify your residency dates. If you are not selected, applications will reset in the next calendar year, and you will need to apply again.

About DINALAB

Digital Naturalism Laboratories (Dinalab) is a jungle prototyping studio founded in 2019. Our lab is fully equipped with Laser Cutter, 3D printers, hand tools, textile tools, and more! The prototyping facility is located in the Soberanía Rainforest in Panama. Our goals are to:

We are also keen on documentation and open-source dissemination of all knowledge in a variety of media! Whether you are a scientist, artist, designer, hacker, or anyone excited to explore nature and technology you will find something interesting at Dinalab.

Dinalab was established by Andrew Quitmeyer and Kathleen Kelly in 2019. They live and work in Dinalab while doing freelance jobs online to cover the costs of running the laboratory and hosting open workshops for local and visiting communities.

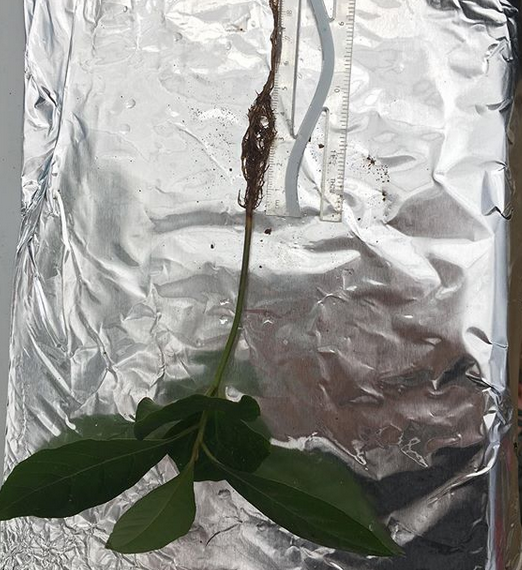

Teaching a workshop for their series about maker communities and having the students create simple experiential tools to explore plant physiology!

Rachel Page’s Bat Lab at the Smithsonian Tropical Research Institute has been hosting a monthly outreach “Bat Night” in gamboa Panama, for quite some time. DINALAB figured it was about time they had their own bat signal!